Augers come in all different shapes, sizes and designs. Plus, they have several different applications you may not know about. Let’s jump straight in and find out what type of auger you need for your next job.

What are augers?

In very simple terms, an auger is a device used for boring holes into a variety of different surfaces, such as soil, wood, ice, stone, rock and more. These unique devices come in two main categories – handheld and machine.

Handheld augers have been around for centuries, however, since the industrial revolution, augers became more technologically advanced. Despite the advancement in technology, the basic function of an auger still remains the same.

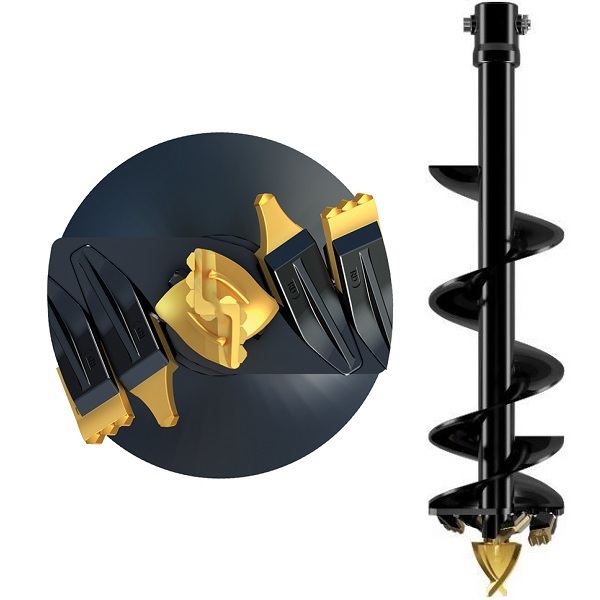

Augers feature a helical screw blade that effectively drills a hole into the desired surface. But the impressive thing about an auger is that it doesn’t just create a hole. It also allows you to remove all of the displaced material from the hole.

Today, augers are used in all sorts of industries, from construction to agriculture. Some are still handheld, but the majority of use cases for augers today include machines like excavators. You can also find direct drive augers that use a hydraulic motor, and planetary augers that use a gear drive system for heavy-duty use.

What are augers used for?

There are several applications for augers, from basic handheld devices to much larger industrial machinery. Let’s take a look at some of the different types of augers and their applications.

Handheld augers

Handheld augers are much smaller and can be simple manual devices or powered by a small engine. These can be used for basic tasks such as drilling holes in wood for woodworking, creating holes in soil for fenceposts, or even in ice for ice fishing.

Agricultural augers

In an agricultural setting, augers are usually attached to another piece of machinery such as a tractor. They are used for a variety of tasks including foundation work, planting trees or even managing grain.

Industrial augers

Much larger augers are used in many industrial settings. They may be attached to an excavator or a standalone boring machine. The uses for these augers are quite diverse, including horizontal boring in mining, drilling through rock and shale or boring through concrete and other heavy surfaces.

Different types of augers – which one do you need?

Several auger types can be attached to earthmoving equipment such as an excavator. When used in this manner as an attachment, there are many different uses. Let’s look at some common types of heavy-duty augers and the main functions you can use them for.

Tungsten augers

Tungsten is well-known as an extremely tough metal. You can buy tungsten auger attachments in several sizes and lengths, and these are ideal for use with clay or rocky ground. Of course, there are several varieties available, but tungsten augers usually feature a conical head for more precise drilling.

Tungsten augers are usually used with a slower drilling process than others, which is they’re more suited to clay or rocky ground. As such, you would use tungsten augers more in an agricultural setting, but they can also be suited to other ground boring applications provided the surface isn’t solid rock or something harder.

Rock combo augers

Rock combo augers are a heavy-duty product used for drilling through rocky surfaces. Different brands will have slightly different designs, but overall, the auger cutting head is the most important part. Teeth are mounted on the auger which helps to break up rocky surfaces and allows the auger to move through more easily.

Rock combo augers are often used in mining applications, such as drilling for fossil fuels. But they are also used for other ground applications where the surface is too hard, rocky or complex for a regular auger to be effective. Being a combination attachment, you can use a rock combination auger for other purposes, too.

Dedicated rock augers

When you’ve got seriously rocky ground to work with, only a dedicated rock auger will do the trick. These specialist augers use a rotating pick tooth to allow for better drill penetration. It’s important when choosing an auger to get the right one for your needs. For example, dedicated rock augers should never be used in normal soil or clay, as it’s likely to cause excessive wear.

Many dedicated rock augers feature a short flighting, which encourages regular removal of excess rock and soil, and also allows cool air into the hole. So, whether you’re drilling in light rock or very heavy rock, there’s a dedicated rock auger out there perfect for your needs.

Are you looking for the right auger?

Whether you need dedicated rock augers, tungsten augers, rock combination augers or attachments, Earthmoving Equipment Australia has got you covered. We stock a huge range of augers suitable for all applications and suited to a range of mini diggers and excavators. No matter the brand of machine you use, we’ve got compatible augers. Best of all, we also offer free fitting and customisation if you need something a little more specific. Contact our team today and get the right auger for your needs.